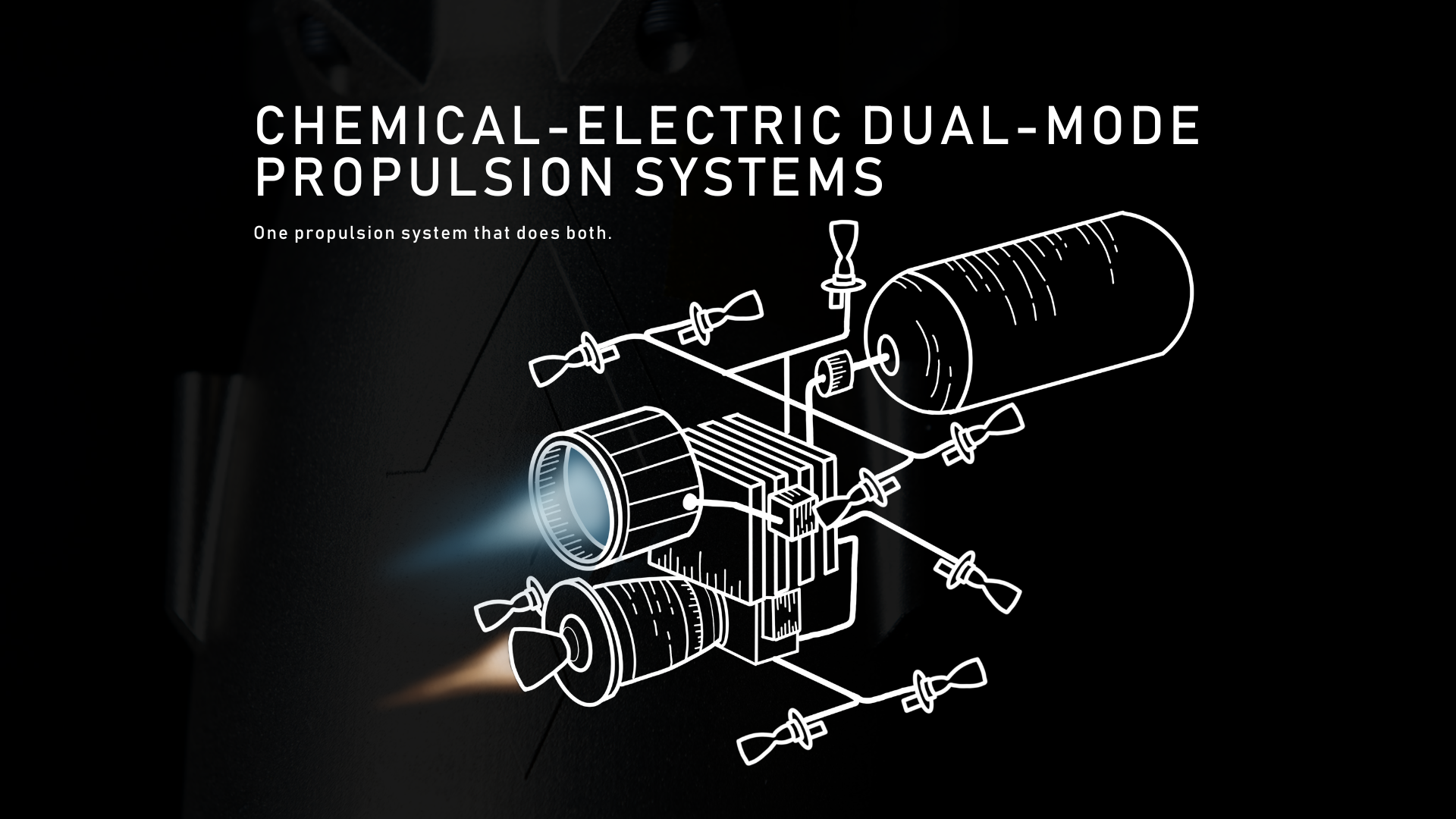

Agile Space is creating chemical-electric dual-mode propulsion systems

September 13th, 2024 – Agile Space Industries presented a technical talk on a new research and development program to develop a chemical-electric dual-mode in-space propulsion system at the AIAA Technical Symposium.

Recently, at the AIAA Technical Symposium, Will Francis, the CCO of Agile Space, presented a new research and development program that Agile Space Industries has been working on.

The audacious goal is to develop a propulsion system that operates in both a dynamic, high thrust mode and an efficient, low-thrust mode, harnessing the strengths of both chemical and electric propulsion while using the same fuel. This gives mission planners more flexibility and spacecraft builders greater mass efficiency.

But what makes this program so unique? Why is there a need for it, and what problem is it solving? Let’s break it all down. For this we have to start at the beginning. At the dawn of the space age, spacecraft rapidly grew from tech demonstrations to useful platforms and the need for in-space propulsion to precisely locate them in the right orbit emerged.

Decades of research by dedicated chemists found chemicals that had the right combination of critical properties for space: liquid over wide temperature ranges, low vapor pressure, resistant to degradation over time, non-corrosive, insensitive to shock, high density, reliable and prompt operation, and high performance. Hydrazine was and still is the best choice for in space storable propulsion. While toxic by skin contact and a vapor inhalation hazard, hydrazine’s stability meant systems could be entirely enclosed, with no venting required. Hydrazine was traditionally used in a bipropellant system with NTO or as a monopropellant, simplifying the spacecraft. But monopropellant systems do not have as much performance as bipropellant systems, and the search for more performance continued. Because of hydrazine’s low flame temperature and the proliferation of solar powered satellites over the following decades, it was possible to use electrical power to augment a hydrazine thruster, increasing the flame temperature and exhaust velocity. First as resistojets, then arcjets, the achievable performance of hydrazine systems climbed from 230 seconds for non-augmented hydrazine, to 300 seconds with resistojets, and 500 seconds with hydrazine arcjets.

The quest for more performance did not stop there. With electrically powered thrusters having a much higher potential for performance, not limited by the bond energy of chemical compounds, the promise of high-performance electric propulsion was obvious. After the Cold War ended, advancements in hall effect thrusters by the Soviet Union was adopted into across space industry. Hall effect thrusters, with specific impulses of 1500 – 3000 seconds, quickly gained interest for high ΔV missions that could accept the low thrust. These thrusters needed to use very special inert gases for their propellant, such as Xenon.

But not all missions can be done with only low-thrust propulsion. Higher thrust operating modes are useful for spacecraft for conjunction avoidance, rapid orbit transfer, or anytime a maneuver needs to be performed quickly to minimize interruptions to revenue generation.

Spacecraft would adopt ‘hybrid’ approaches, including both noble gases for EP thrusters and chemical propulsion thrusters for the higher thrust maneuvers. EP thrusters, due to their high-power demand, frequently prevent spacecraft from simultaneously performing their essential functions while doing maneuvers. Chemical thrusters, in contrast can quickly perform maneuvers with much lower power, minimizing or eliminating interruptions to service.

Over the past decade, EP thrusters have made significant progress in adopting other propellants, moving away from expensive and rare gases like Xenon to more common gases such as Krypton and Argon. Significant work has also been performed on ‘air breathing’ electric propulsion systems which will scoop air from the upper reaches of our atmosphere and running it through EP thrusters tuned for nitrogen, while being tolerant to the corrosive oxygen radicals.

Advances in the ability for electric propulsion systems to be more flexible with propellant gases, including nitrogen, has opened an opportunity to make electric propulsion systems that could operate with hydrazine. The exhaust products of hydrazine are 88% Nitrogen by weight, while air is 78% Nitrogen. But with hydrazine, the remainder is hydrogen, which is a much less corrosive and much lighter element than oxygen, resulting in less wear and tear on thrusters while providing higher performance.

At the same time, the space domain has become less safe, with new spacecraft needing to respond faster to conjunction warnings or quickly maneuver for survivability. Rather than needing a separate chemical propulsion system for agile maneuvers and efficient maneuvers, spacecraft soon can have one propulsion system that does both. Instead of budgeting trade-offs ahead of time when the spacecraft is in early planning stages, a chemical-electric dual-mode propulsion system will allow flexible, agile operations and fully utilize all the available propellant.

Maximizing freedom in space means having flexible operations and not needed to lock in a delta-v split between EP and chemical systems ahead of time.

To develop and commercialize these flexible systems, ground testing is essential to prove the reliability and performance of EP thrusters that use hydrazine. Agile is a world leader in rapid delivery of propulsion solutions to maximize freedom in space, which is why we are developing our Menefee test stand. Our new test stand will be a high vacuum test stand compatible with hydrazine so the next generation of EP thrusters can be tested, developed, and qualified. In addition, we are developing standards for integration of EP thrusters into hydrazine systems, so they can be rapidly tested at our facilities, or integrated into future propulsion architectures as standard components.

A no-compromises spacecraft propulsion system that captures the best of chemical and electrical propulsion with no drawbacks is within reach. Agile is creating the infrastructure and interfaces to make it happen.

Technical talk presented by: Will Francis

Chief Engineer on program; Lars Osborne

Story written by: Lars Osborne

For more information send an email:

bd@agilespaceindustries.com

For media contact:

Juleah Kaliski

juleah.kaliski@agilespaceindustries.com