Agile Space Receives SpaceWERX Contract for Innovative Mobile Payload Processing Center

A natural extension of its shipping containers for fuel and remote engine testing, Agile’s mobile processing units provide secure, safe, and clean environment for responsive on-demand USG launches.

DURANGO, Colo. - February 5th, 2024 – In-space propulsion solution provider Agile Space Industries (Agile) today announced it has received a Small Business Innovation Research (SBIR) Phase II contract from SpaceWERX, the innovation arm of the U.S. Space Force and a part of AFWERX, and the Air Force Research Laboratory. With more than 300 companies vying for $34 million in investment awards, Agile was one of 19 companies selected as winners of the 2023 SpaceWERX Tactically Responsive Space (TacRS) Challenge, sponsored by the Space Safari program office at USSF Space Systems Command, which identifies cutting-edge TacRS concepts that enable the Space Force to respond to the most pressing challenges and emerging on-orbit threats by 2026.

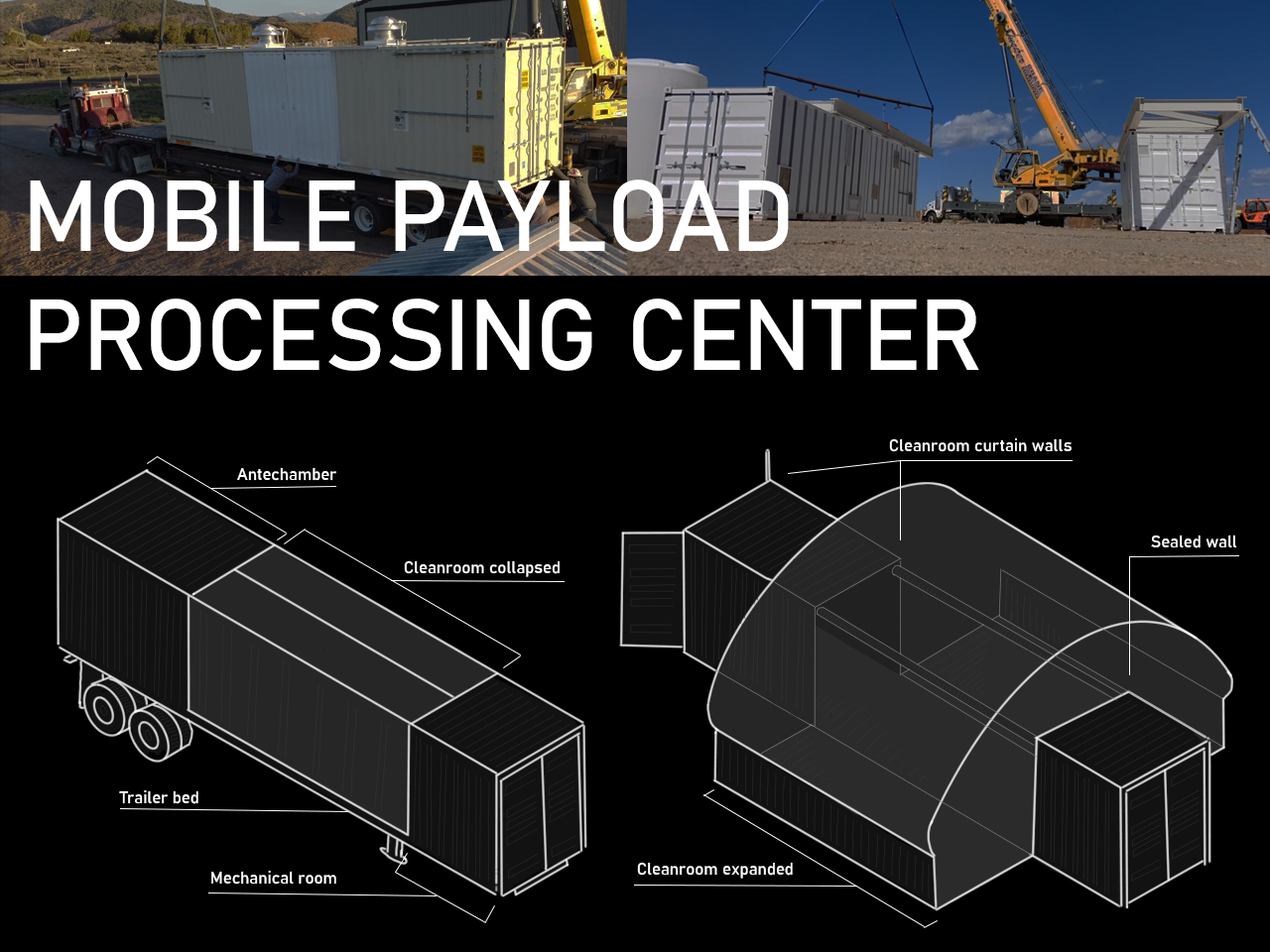

SpaceWERX awarded the contract to Agile for its Mobile Payload Processing Center (MPPC) which will enable the U.S. government to increase mission effectiveness in remote locations.

The MPPC provides the ability to create a safe and secure mobile environment for on-demand, tactically responsive launches – where there can be mere hours to prepare and process a payload for launch

The MPPC is a 40-foot-long high cube shipping container that fits on a flatbed truck and is expandable to provide over 500 square feet of ESD safe working space in a Class 10,000 (ISO 7) cleanroom. In addition, integrated fire suppression and chemical washdown is native to the system, making it a highly capable, roomy, versatile and unparalleled system for remote payload processing.

With its expandable capacity, the MPPC easily accommodates the processing of standard ESPA payloads all the way to those larger than ESPA Grande, satisfying a large portion of the space industry’s payload processing needs. It provides a generously sized clean, safe, and secure operational footprint for multiple operators to simultaneously work on large payloads.

“Since our early days, Agile has been dedicated to creating cutting-edge, innovative solutions that solve our commercial and government customers’ unique challenges, including offering remote test services, nimble additive manufacturing processes, custom engine solutions, and even fueling shipping containers,” said Kara Grubis, Agile’s vice president of Engineering. “While we initially designed these mobile units to support rocket engine testing services in the Mojave desert, we’ve found they’re highly adaptable and a natural extension of our core propulsion solutions. We’re grateful and excited to be recognized by SpaceWERX for our ability to reimagine what’s possible, bringing novel solutions to the space industry, and beyond.”

In addition to the many payload processing needs at remote locations, including existing launch facilities, Agile’s underlying platform can also be outfitted as a mobile test stand, hypergolic decontamination unit, or any other temporary shelter or laboratory required for non-defense purposes. The versatility of the mobile facility also extends to commercial uses as well, serving as a containerized scientific laboratory for medical, research, and educational programs. “This is really a game changer, not only in the space industry, but for so many commercial organizations who have remote needs,” Grubis added.

“The concept of Tactically Responsive Space (TacRS) requires all stakeholders to embrace a get-it-done, adaptable, ‘MacGyver style’ approach to get after the mission and outpace the threat,” said Capt. George Eberwine, program manager in the Space Safari program office and the Technical POC for the MPPC effort. “Innovative solutions, like the Mobile Payload Processing Center, could provide the U.S. Space Force flexibility in times when traditional solutions might be compromised.”

About Agile Space Industries:

Agile Space Industries is an in-space propulsion solution provider, specializing in hypergolic chemical systems. Agile has industry leading expertise in the design of chemical-propulsion rocket thrusters. Rapid prototyping, development, qualification, and delivery is catalyzed by in-house additive manufacturing and engine test capability. The company employs more than 65 people between facilities in Durango, Colorado and Mount Pleasant, PA that specialize in component, system development, test and additive manufacturing. Agile is working with numerous primes as well as the US Government on various spacecraft and launch vehicle propulsion projects. For more information, visit agilespaceindustries.com.

About Space Safari:

The Space Safari Program Office, under U.S. Space Force Space Systems Command (SSC), was created in January 2021 to respond to high-priority, urgent space needs by rapidly acquiring, integrating, and executing missions in support of USSPACECOM requirements and other combatant commander urgent operational needs.

Space Safari is the lead organization driving the USSF forward on cutting edge Tactically Responsive Space (TacRS) capabilities. This requires an end-to-end approach for employing space capabilities to provide options to commanders responding to threats in space. Space Safari is active across the entire spectrum of the TacRS mission set, to include acquiring space vehicles, integrating payload sensors, modifying ground architecture, developing concept of operations for mission planning, shaping mission parameters to address specific missions, and conducting initial on-orbit operations. Space Safari is also actively engaging with community partners on policies/procedures, tabletop exercises, and evaluation of operational concepts.

About AFRL:

The Air Force Research Laboratory is the primary scientific research and development center for the Department of the Air Force. AFRL plays an integral role in leading the discovery, development, and integration of affordable warfighting technologies for our air, space and cyberspace force. With a workforce of more than 12,500 across nine technology areas and 40 other operations across the globe, AFRL provides a diverse portfolio of science and technology ranging from fundamental to advanced research and technology development. For more information, visit afresearchlab.com.

About AFWERX:

As the innovation arm of the DAF and a directorate within the Air Force Research Laboratory, AFWERX brings cutting-edge American ingenuity from small businesses and start-ups to address the most pressing challenges of the DAF. AFWERX employs approximately 325 military, civilian and contractor personnel at six hubs and sites executing an annual $1.4 billion budget. Since 2019, AFWERX has executed 4,697 new contracts worth more than $2.6 billion to strengthen the U.S. defense industrial base and drive faster technology transition to operational capability. For more information, visit: afwerx.com.

About SpaceWERX:

As the innovation arm of the U.S. Space Force and a unique division within AFWERX, SpaceWERX inspires and empowers collaboration with innovators to accelerate capabilities and shape our future in space. Headquartered in Los Angeles, SpaceWERX employs 28 military, civilian and contractor personnel executing an annual $457 million budget. Since it was aligned under AFRL in Aug. 2021, SpaceWERX has executed 906 contracts worth more than $690 million to strengthen the U.S. defense industrial base and drive faster technology transition to operational capability. For more information, visit: spacewerx.us.

The views expressed are those of the author and do not necessarily reflect the official policy or position of the Department of the Air Force, the Department of Defense, or the U.S. government.

Media Contact:

Jodi Sorensen, on behalf of Agile Space

jodi@littlecandlemarketing.com

206-856-4202 cell