A Look Behind the Mobile Payload Processing Center SpaceWERX Award

March 5th 2024 we announced Agile was awarded a Small Business Innovation Research (SBIR) contract by SpaceWERX, which acts as a venture fund for the U.S. Space Force. With 300+ companies applying for the awards, our Mobile Payload Processing Center was one of the elite 19 solutions selected. So exciting! The awards were made through the 2023 SpaceWERX Tactically Responsive Space (TacRS) Challenge, which was designed to discover cutting-edge concepts that could enable the Space Force to quickly respond to emerging on-orbit threats by 2026.

To provide some more background on the solution and the SpaceWERX contract award, we sat down for a chat with Agile’s Vice President of Engineering, Kara Grubis.

Most people think of Agile’s propulsion and spacecraft engines. Can you tell us more about how the Mobile Payload Processing Center (MPPC) came to be?

Many may not remember this, but Agile Space started as a mobile testing platform company. Our founder Daudi Barnes would drive a specially outfitted hot fire test facility to remote customer sites to test thrusters. We’ve obviously added a lot of sophistication, customization, and variety into our propulsion solutions since those early days, but creating innovation where it didn’t exist before has always been foundational to Agile. Our team prides itself on bringing these kinds of novel concepts into reality and helping customers solve problems.

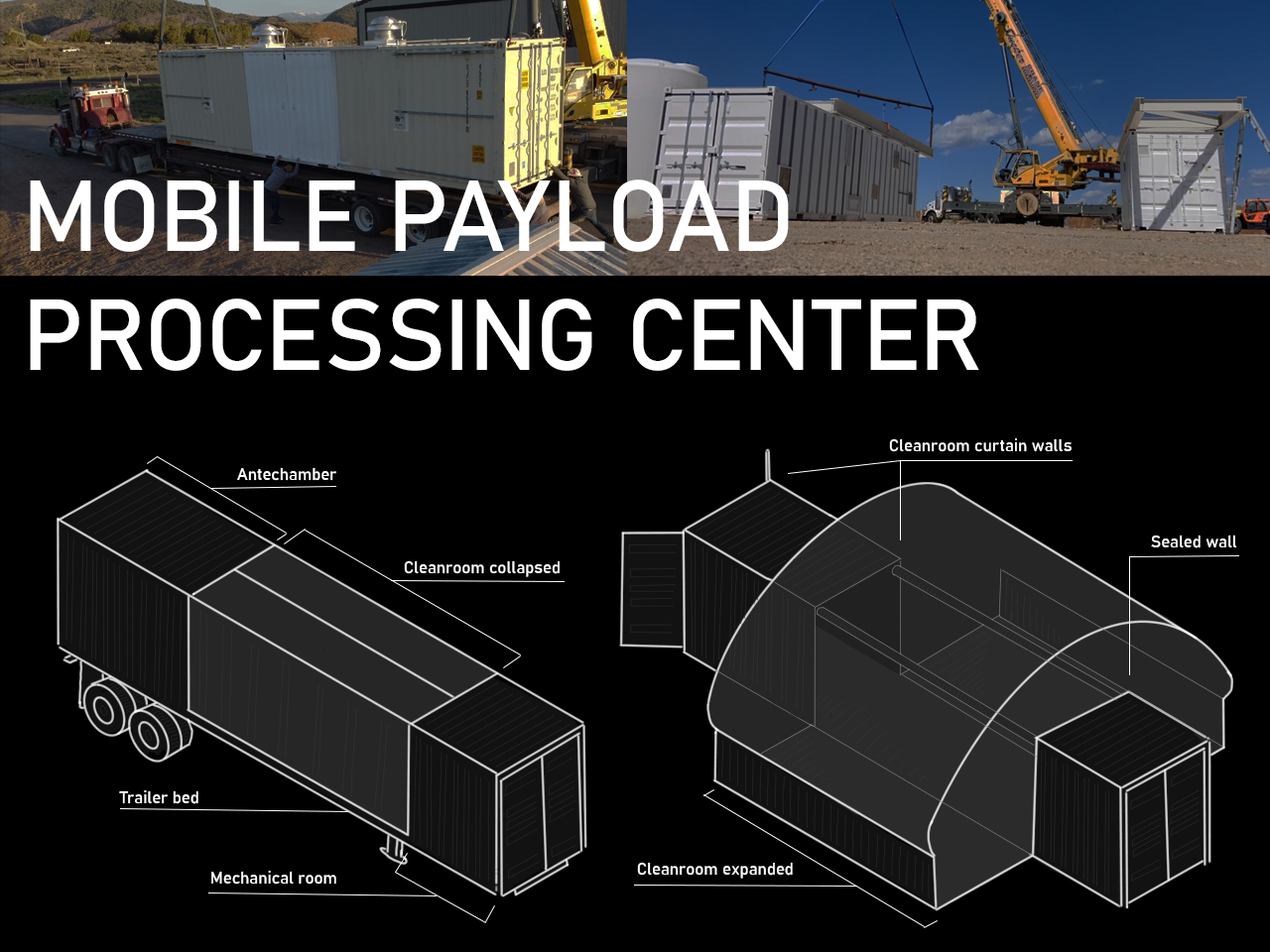

When we looked at the industry, we found many different portable clean room solutions, but they were unable to expand, offering typically less than 200 square feet of working space and less than 9 feet of height. That’s really limiting for most space applications. Our solution expands to provide approximately 500 square feet of working area and 15 feet of height making it able to accommodate payloads that were previously restricted to permanent on-premises cleanrooms. It’s a real game-changer in the industry!

Specifically, for the SpaceWERX Tactically Responsive Space Challenge, we proposed a solution that is a natural extension of our previous experience. We designed a “right-sized” mobile unit to provide quick support where needed. The MPPC is a 40-foot-long high cube shipping container that fits on a standard flatbed truck (e.g. doesn’t require a double-wide semi-truck which brings travel constraints and costs) and is expandable to provide more than 500 square feet of ESD safe working space in an ISO 7 cleanroom environment. As part of designing a safe working space, we’ve also integrated fire suppression and chemical washdown, complete with fluid catchment built under the container, so any chemical contamination can be safely isolated until the time it can be dealt with properly. The ancillary applications for this type of mobile unit are vast, and as we’re learning, extend way beyond the space industry.

Why would these mobile units be critical for the USAF?

Why do you think SpaceWERX was intrigued by this idea?

The Defense industry needs cutting-edge, innovative solutions to efficiently execute tactical responsive launches. It’s a critical element of national security in space, and one that reduces the risk of potential threats. For instance, they may have only a couple hours to set up a comprehensive payload integration process at a launch site. There aren’t viable options on the market today that are easy to transport and set up, that are also expandable to accommodate larger spacecraft, and offer built-in decontamination capabilities. The versatility of our mobile facility solution extends to many other use cases beyond responsive launch too. Why shouldn’t the MPPC be used on an ocean liner, in the middle of a desert or ice field? This is the kind of creative thinking and agility in problem solving that we can provide…our name IS Agile after all.

How could commercial companies benefit from the mobile units?

How big is your imagination? For non-military customers where money is more of a constraint than time, the MPPC could be used for commercial satellite work in locations without a resident payload processing facility. This is probably the most immediate and obvious example. The MPPC can easily accommodate processing standard ESPA payloads all the way to those larger than ESPA Grande. This adaptable size capability allows for the processing of large payloads with many people involved, which satisfies a large portion of the commercial space industry’s launch needs.

Additionally, the underlying platform could be outfitted as a mobile test stand, hypergolic decontamination unit, or any other temporary shelter or laboratory required for non-defense purposes. As the commercial space industry has seen many new players recently, the MPPC represents a cost-effective and flexible method of getting facilities to any location. As many players seek to drive down launch costs using economies of scale, the MPPC provides sufficient square footage and height to handle larger commercial payloads.

There are many compelling use cases for the MPPC beyond the space industry as well. The MPPC is a flexible platform for any science-related work necessitating a mobile controlled environment – perhaps near a rainforest, glacier, or volcano. With the system being designed to operate off of a high-clearance semi-trailer, it can be transported over terrain that is difficult for existing solutions to access.

What are the next steps now that you’ve received the contract?

We’re already hard at work – doing functional and technical design reviews and meeting with suppliers. While we have 15 months to deliver our solution to SpaceWERX, we’re targeting a demo by the end of the year. In addition to developing this mobile facility, our team is also providing our expertise to a wide range of unique customer missions, supporting lunar landers, deep space propulsion, fueling tanks, remote test facilities, custom engines, and more. There’s a lot on our plates, and we wouldn’t have it any other way.